HEMPCRETE INSULATING LINING

What is hempcrete?

Hempcrete is a composite made of natural materials, lime and hemp. The lime component consists of air lime that is formulated to speed up the setting process. The hurds are made using hemp stalks. Hemp is a plant that can be grown without using plant protection chemicals, requires little water and contributes to agricultural soil regeneration. The combination of lime and hemp creates a natural concrete which is lightweight, or ultra-lightweight even. Its thermal mass and vapour permeability properties result in high-performance buildings capable of meeting current and future thermal regulations.

Hempcrete is one of those bio-based materials that can be used to build, renovate and restore all types of building, from houses and apartment blocks to service and public sector buildings and all types of built heritage, from traditional buildings to listed historic buildings.

Hempcrete is made by mixing lime and hemp in proportions adapted to the work to be done. This makes it very versatile, and it can be used to build insulating walls, linings, roofs, screeds, attic spaces and renders.

What are the benefits of hempcrete?

Areas of use. It can be used to build self-insulating walls, roofs and screeds It can be adapted to all types of building project including new builds and renovations.

It is not a load-bearing material. Consequently, when building walls, it is cast around a primary or secondary structural frame made of timber, metal or concrete. It is also used to replace deteriorated cob in half-timbered walls. As an insulating lining, it can be cast on all standard mineral substrates.

Casting methods. Initially hempcrete was cast manually. Later, specific mechanical projection solutions arrived on the market, making processes much more efficient. A concrete mixing station combined with a concrete mixing truck and a conveyor belt is also an excellent solution frequently used by professionals to cast insulating roofs and screeds. Nowadays, workshop-prefabricated walls can also be produced for a faster build, without losing any of the benefits of a material that provides excellent thermal and moisture control performances.

Thermal performance. The first feedback for newly built houses with hempcrete showed that bioclimatic houses can be built with drastically reduced heating costs and no air conditioning. On average, the estimated cost of heating for this type of house is around €1-2 per m². But it can also be even lower, as proven by the €35 a year bill paid by the owners of a house built by the architect JM Naumovic in Vendée.

Casting Tradical® Hempcrete as an insulating lining for walls

I. The idea behind Tradical® hempcrete as an insulating lining

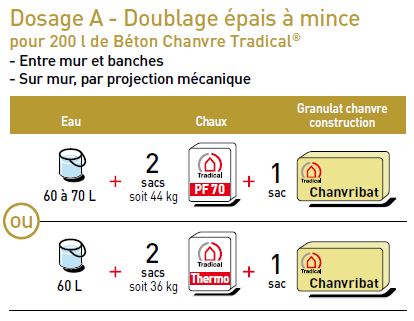

Tradical® hempcrete insulating lining is a combination of Tradical®PF 70 or Tradical® Thermo formulated air lime and Chanvribat® (‘Granulat Chanvre Bâtiment’ certified). It meets the eco-efficiency objectives that are now applied to renovation projects, from renovating houses to the restoring of historic buildings.

A hempcrete insulating layer that is cast directly on the substrate without any joints or air space guarantees continuity between materials, avoiding thermal bridges in particular, which are often present when conventional insulation materials are used.

It not only improves the existing characteristics of the walls on which it has been cast, but also brings its own set of properties that are unrivalled on the renovation market:

- Dynamic absorption of temperature variations

- Dynamic absorption of relative indoor moisture variations

- Eliminates the ‘cold wall effect’

The end result is excellent insulation, a pleasant living atmosphere and healthy indoor air regardless of season or weather.

II. Landmark materials for long-lasting insulation

This bio-based insulation layer contributes to the durability of the renovation and the building as a whole thanks to:

- its moisture-regulating properties,

- its dimensional stability – no sagging – and the insulating properties stay the same throughout.

In addition, hempcrete insulation stays free from bacterial attacks, insects such as termites, fungi (thanks to the high pH of air lime) and rodents!

Tradical® hempcrete has been tested for its service life. It can resist 20 freeze/thaw cycles, which is comparable to the service life of limestone.

By installing this type of insulating lining, buildings can withstand the vagaries of time and you can make significant savings on future maintenance or renovation costs. And it is worth noting that all performance ratings stay the same for the whole service life of the hemp-lime composite (Ref.: MAP 04B1 05 01, LCA for a 100-year period).

III. A flexible solution

The flexibility offered by Tradical® hempcrete insulating lining provides efficiency and savings in many areas. The thickness of the cast material varies from 5 to 20 cm depending on energy-saving objectives, the building’s orientation and surroundings, etc. Builders have a choice of several casting methods:

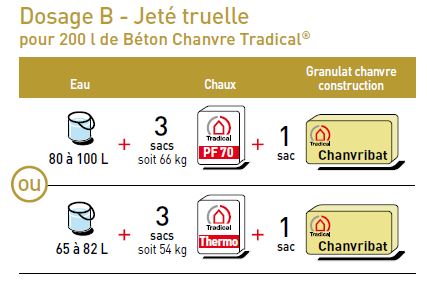

- manually using the traditional trowelling method for small thicknesses,

- manually, by pouring the hempcrete in between the wall and shuttering,

- mechanically, by spraying the hempcrete in between the wall and shuttering or directly onto the wall.

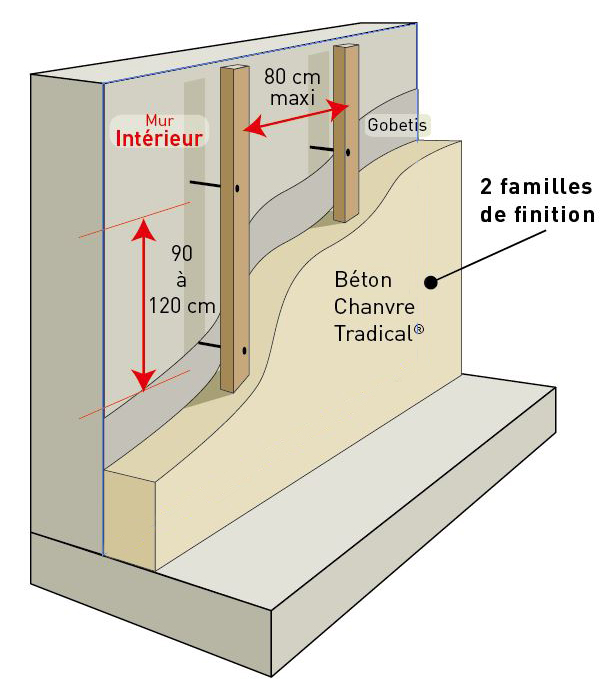

For practical reasons, a secondary structural frame is used for medium-to-large thicknesses. All conduits and pipework have to be installed before beginning any casting work.

Thick lining

Over 15 cm

Methods of application

– Infill between the wall and shuttering

– Mechanical projection

– Trowelling

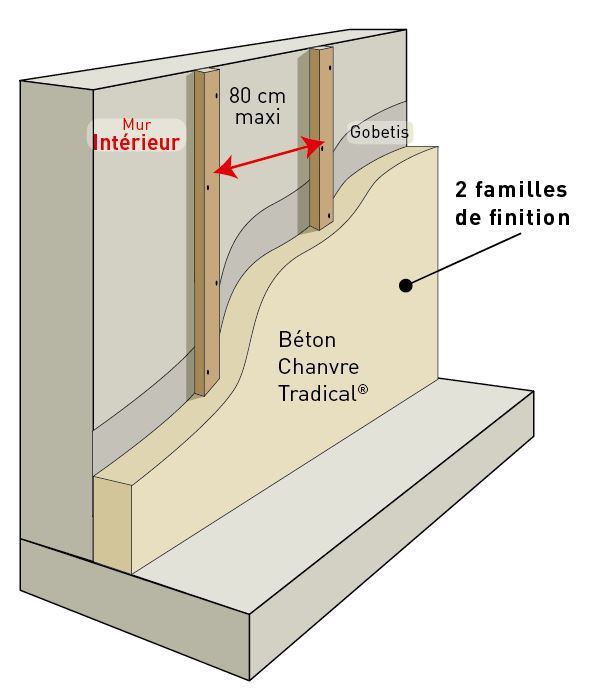

Medium lining

From 11 to 15 cm

Methods of application

– Infill between the wall and shuttering

– Mechanical projection

– Trowelling

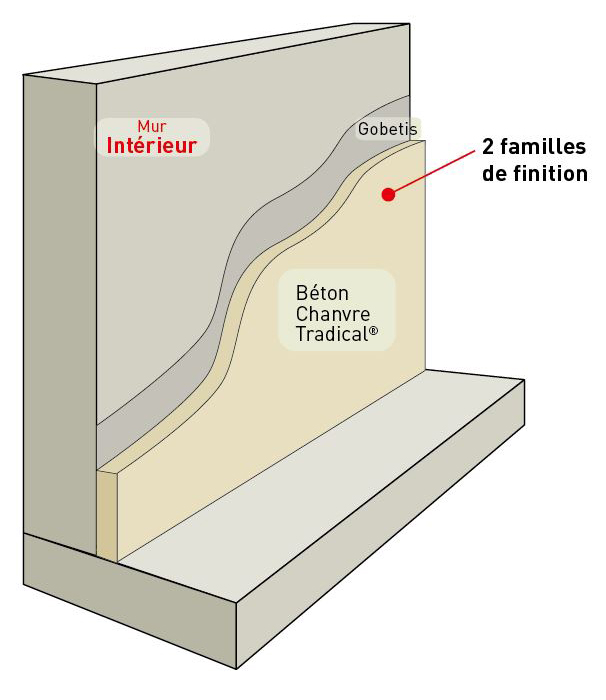

Thin lining

Up to 11 cm

Methods of application

– Mechanical projection

– Trowelling

Finishes for Tradical® Hempcrete Insulating Lining

Several perfectly compatible types of Tradical® air lime finishes can be applied. They contribute to the overall effectiveness of the lining, notably where moisture transfer is concerned, as the materials used have the same properties.

The following solutions are available depending on how even the surface of the Tradical® hempcrete lining is, and the atmosphere to be created:

- Tradical® Hemp render, which provides additional thermal, acoustic and moisture-regulating qualities.

- Tradical® Lime render mixed with sand for a traditional lime-based finish.

- Tradical® Décor render for a contemporary look.

- Tradical® Lait de

Chaux (milk of lime) to make a limewash applied al secco, which adds colour to the surface of the insulating lining while keeping the texture of the hemp and lime insulation.

Hygrothermal renders

- Tradical® PF 80 M + Chanvribat®

- Tradical® Bâtir + Chanvribat®

Mineral renders

- Tradical® PF 80 + sand

- Tradical® PF 80 M + sand

- Tradical® Décor

Benefits of Tradical® Hempcrete Insulating Lining

1-It can be applied to all mineral substrates

Buildings in France are made of a wide range of different materials. Thanks to its inherent characteristics, Tradical® hempcrete lining can be used on any substrate: stone walls, brickwork, pisé, and even breeze blocks or aerated concrete, as well as on walls made with several very or completely different materials. This hempcrete insulating lining fits in with all building methods, regardless of the region or vernacular building style.

2-It meets French RT Elément par Elément energy-efficiency standards

For opaque vertical walls with thermal performance requirements between 2.2 and 2.9 m².K/W, depending on the geographical location (Reference document: Order dated 22 March 2017).

This natural insulation is also ideal for projects that are eligible to receive the HPE Rénovation (high energy efficiency for renovations) or Bâtiment Biosourcé (bio-based building) certifications.

The thermal conductivity coefficient (λ of 0.085 W/m.k with Tradical® PF 70 and λ of 0.076 W/m.k with Tradical® Thermo) enables energy-efficiency requirements to be met. This gives an R value of between 0.6 and 2.6 m².K/W, depending on the thickness applied (e.g., from 5 to 20 cm).

3-It gets rid of uneven surfaces

Old buildings are lovely, but can also be a headache when it comes to uneven surfaces, which may be have been damaged to varying degrees. This lining – applied over a base coat – fills all the gaps and hollows, and gets rid of any unevenness that may hinder the work to follow, without having to prime the surface in any way beforehand.

4-It can be used for all types of renovation

Big or small renovations and on all types of building from houses and apartment buildings, to office blocks and public buildings.

5-Work is streamlined

No adhesive tape or vapour barrier required, the mason takes care of all the work.

6-It preserves the character of traditional buildings

As it is easy to work with and cast, all interior building features, such as openings, recesses and so on, can be dealt with using formwork. Preserving all the characteristics of a building is effortless.

7-It maintains the vapour permeability of walls

This overlooked phenomenon of condensation on interior walls can cause several issues.

A hempcrete insulating lining ensures the essential transfer of water vapour by respecting the natural and inherent behaviour of existing buildings.

8-It does not overload the structure of buildings

As a very lightweight material, thanks to a density of 280 kg/m² (with Tradical® Thermo), it enables work to be performed that respects the mechanical properties of buildings to be renovated.

The properties of Tradical® Hempcrete Insulating Lining

The durability of Tradical® Hempcrete Insulating Lining

This bio-based insulation layer contributes to the durability of the renovation and the building as a whole thanks to:

- its moisture-regulating properties,

- its dimensional stability – no sagging – and the insulating properties stay the same throughout.

In addition, hempcrete insulation stays free from bacterial attacks, insects such as termites, fungi (thanks to the high pH of air lime) and rodents!

Tradical® hempcrete has been tested for its service life. It can resist 20 freeze/thaw cycles, which is comparable to the service life of limestone. By installing this type of insulating lining, buildings can withstand the vagaries of time and you can make significant savings on future maintenance or renovation costs. And it is worth noting that all performance ratings stay the same for the whole service life of the hemp-lime composite (Ref.: MAP 04B1 05 01, LCA for a 100-year period).

Casting methods for Tradical® Hempcrete Insulating Lining